A pratical guide to protecting your tools, equipment, and products

Whether you’re transporting delicate instruments, valuable tools, or high-precision parts, choosing the right outer case is only one part of the equation. What’s inside and how well your items are secured and protected often makes the difference between safe arrival and costly damage.

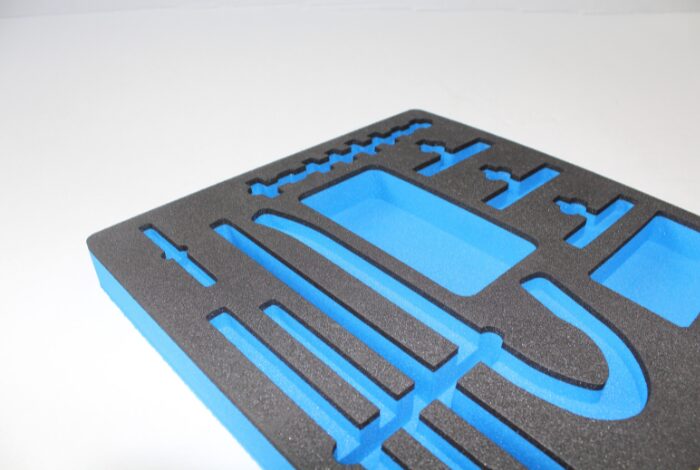

While foam inserts may not seem remarkable at first glance, custom foam interiors are one of the most effective ways to improve the safety, organisation, and longevity of the items inside your case.

Understanding how foam inserts work and why they’re so widely used across various sectors, including engineering, manufacturing, medical, and field services, can help you make better decisions when sourcing or upgrading your packaging.

Contents

Eliminating unwanted movement

One of the most common causes of transit damage is simply movement. When items aren’t held securely in place, even small jolts during loading, driving, or handling can cause them to shift inside the case. This leads to impacts between the item and the case wall, and sometimes between items themselves within the case.

Over time or under repeated conditions, these knocks can result in scratches, misalignments, or more severe damage. It doesn’t take much for a precision instrument or a calibrated tool to be knocked out of tolerance.

Custom foam inserts solve this by shaping themselves around your equipment. Rather than relying on loosely padded cavities or generic square-cut recesses, purpose-designed foam hugs every contour, creating a snug and stable fit.

This prevents the contents from bouncing around and dramatically reduces the stress placed on them in transit.

Managing impact and shock

Even when movement is controlled, your equipment still faces the challenge of impact. Protective cases can and do get dropped, bumped, or thrown.

Foam acts as a cushion against these inevitable forces. By compressing under load and then returning to shape, it slows down the force experienced by the object inside, spreading it over time and space. This is often referred to as controlled deceleration, and it’s a key reason why foam is so widely used for high-value equipment.

The type of foam used matters, with factors such as density, thickness, and structure all influencing how well the chosen foam performs. Softer grades may be better for lightweight, delicate items, while denser foams can handle heavier loads without bottoming out. Often, the best results come from layering or combining different materials to absorb a range of impact types, from a single drop to constant vibrations.

Designers can even simulate how the foam will perform under specific conditions, helping to ensure it performs as intended before the prototype is cut.

Protecting surface finished

In many industries, a scuff, dent, or blemish can render a product unusable or, at the very least, unacceptable to the end user.

This is especially true for items with polished, painted, or coated surfaces. Even mild abrasion during transit can leave visible wear. Over time, that can result in rejected deliveries, additional rework, or harm to your brand reputation.

Foam inserts help avoid this by offering not only support, but a soft, non-abrasive interface. Plastazote foam, for example, is often chosen for its smooth texture and gentle handling of sensitive finishes. Combined with the movement control already discussed, it creates a system that protects both a structural and visual level.

Organisation and visual control

Beyond protection, foam inserts also support better organisation. In cases carrying multiple parts or tools, it’s easy to lose track of what’s where.

That’s why shadow boards and colour-layered foam have become popular in many sectors. These use contrasting layers of foam so that if an item is removed or missing, a bright colour is revealed underneath. This gives a clear visual cue that something is not where it should be. For field engineers or technicians, this can help prevent leaving tools behind or starting a job without all the necessary equipment.

The same principle applies in manufacturing or maintenance environments, where consistency and accountability are essential. The insert serves as a visual checklist, simplifying inventory management and reducing human error.

Improving presentation

In some cases, protective foam is also used to enhance how items are presented and protected. This is especially relevant in sales samples, demonstration kits, or product launch cases.

With a well-designed insert, equipment arrives safely and looking presentable. Items are laid out cleanly, consistently, and attractively, often in branded colours or with etched labels. This adds a professional touch and can make a real difference in first impressions.

Even internally, staff can benefit from a clearer, more organised layout. It reduces time spent searching, lowers the chance of misuse, and helps maintain standards across teams.

Customisation and integration

While foam inserts provide internal protection, many protective cases can be enhanced in other ways as well. Additions like handles, stacking feet, or electronic bezels allow the case to serve not just as packaging, but as part of the job itself.

Some cases can be integrated with control panels, wiring, or custom fittings, creating self-contained units for service or fieldwork. Others may include visual branding, instruction markings, or colour coding, all of which can be etched or printed directly into the case or foam.

This level of integration helps bridge the gap between packaging, transport, and actual use, offering a more efficient and user-friendly solution.

Summary

Foam inserts might not get the same attention as the hard plastic shells they sit inside, but they’re vital to the performance of any protective case. They help prevent movement, absorb impact, reduce surface wear, and improve organisation, all of which translate to fewer damages, smoother operations, and better outcomes.

If you’re trying to figure out how to improve your transit packaging or find that current solutions aren’t holding up, it may be time to take a closer look at what’s happening inside the case.

At Suttons, we collaborate with businesses across various industries to design custom foam solutions tailored to the unique challenges you face. Whether you need to protect sensitive instruments, manage tools in the field, or create a high-impact presentation case, we can help you develop a smarter and safer internal setup.

To discuss your requirements or receive advice on designing foam inserts for your protective cases, please get in touch with our team of experts today.