Keep track of your tools and protect your equipment

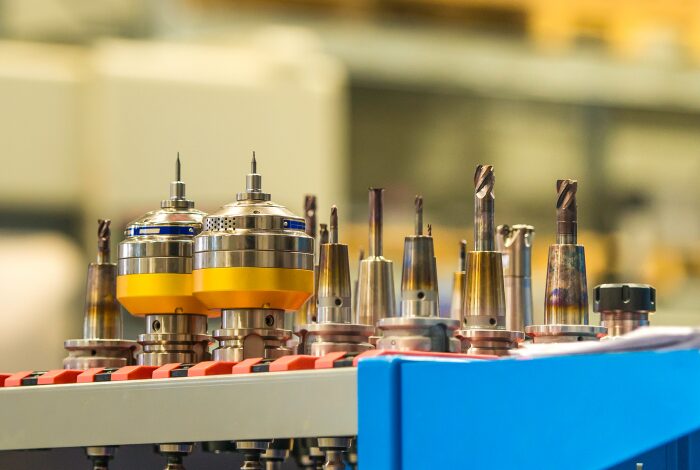

If you’re working on complex equipment in aerospace, automotive, manufacturing, or any high-performance industry, preventing foreign object damage should be a top priority on your safety checklist.

Foreign object damage happens when stray objects, like loose tools, fasteners, or bits of debris, end up where they shouldn’t be. In sectors like aviation, this kind of oversight can result in serious safety issues, not to mention expensive downtime and repairs.

While regular inspections, cleanliness routines, and detection systems are essential, implementing innovative tool control strategies is one of the simplest and most effective ways to reduce the risk of foreign object damage.

In this guide, we’ll talk you through:

- The basics of tool control practices

- Why tool tracking matters

- Practical solutions that keep your tools organised and your operations safe

Contents

Why is foreign object damage a serious concern?

Foreign object damage is a real risk to safety and performance, and multiple high-profile incidents have been caused by a single forgotten tool. For example, an Airbus helicopter crash in 2015 was ultimately traced back to a tool left behind during maintenance. In another case, a screwdriver damaged an aircraft’s propeller and fuselage in 2018.

These incidents show how critical it is to ensure no foreign items are left in or around mechanical systems.

Foreign object damage can occur while servicing manufacturing equipment, vehicles, or machinery that relies on tight tolerances and smooth operation. And when it does, the financial and operational costs can be significant.

What is tool control?

Tool control is exactly what it sounds like: a system for ensuring that every tool used on a job is accounted for before, during, and after work.

The idea is simple: knowing where every tool is supposed to be becomes obvious when something’s missing.

Without an organised storage solution, it’s easy for something to go astray. One misplaced item, whether a spanner in an enginer bay or a torque wrench left behind in a turbine housing, can lead to disaster.

That’s why maintenance teams follow strict tool control practices. These are often backed by regulations from aviation authorities like the UK’s Civil Aviation Authority (CAA) or the US Federal Aviation Administration (FAA).

What do the regulations say?

Here’s a simplified breakdown of CAA Policy (Part 145-2 (Part 145.109), which sets the tone for most tool control practices:

- Identification: Tools must be uniquely labelled and logged in a master list.

- Inspection and calibration: Tools for precise measurements or torque settings need regular checking and calibration.

- Maintenance: Tool inspections or servicing would follow manufacturer guidelines unless there’s proven evidence that a different interval works better.

- Visibility: It should be clear when a tool is due for inspection or unusable for any reason.

In short, the goal is simple: track every tool, check it regularly, and store it properly.

How to put tool control into practice

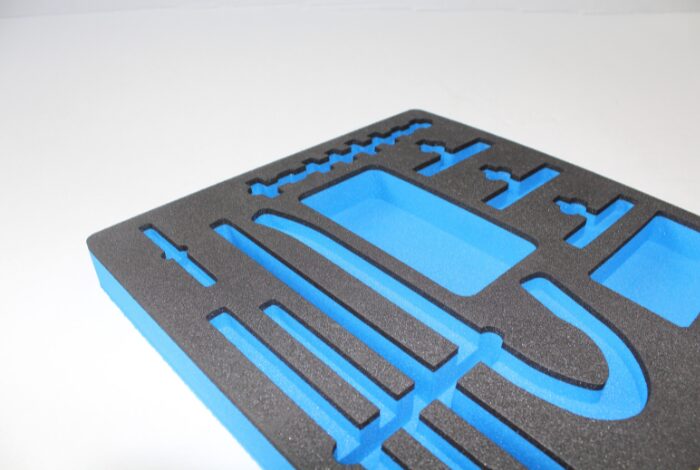

An excellent tool control system starts with clearly defined spots for every tool. That’s where tool control foam comes in.

This foam (sometimes known as shadow foam or shadow boards) makes it easy to organise your toolbox or equipment case. Each tool gets a custom-cut recess in the foam, so it’s instantly obvious if anything’s missing.

Most solutions feature a high-contrast colour beneath the surface layer. When a tool is removed, the bright colour shows through, providing an instant visual cue.

Here at Suttons, we specialise in creating bespoke foam inserts tailored to your specific toolset, whether you’re kitting out a portable case or a full workshop station.

The benefits of tool-controlled foam

Implementing foam inserts for your tools is a practical step that delivers real results.

- Reduces FOD risk: Foam inserts help prevent tools from being left behind in sensitive areas by clearly showing when something is missing.

- Improves efficiency: A well-organised toolkit makes it faster and easier for engineers to find what they need, reducing downtime and speeding up maintenance tasks.

- Protects tools: Foam inserts cushion your equipment during transport or storage, protecting it from damage caused by knocks, vibration, or mishandling.

- Reduces costs: Preventing damage to expensive tools (and the equipment used) means fewer replacements and less unscheduled maintenance.

- Enhances sustainability: Every tool must be accounted for in regulated environments like aerospace. Foam systems make tracking and auditing tools easier, helping you confidently meet compliance standards.

Summary

Whether you’re in aerospace, automotive, manufacturing, or another high-performance industry, tool control is vital for operational safety and reliability.

At Suttons, we’re experts in designing protective foam solutions that keep your tools secure, visible, and accounted for.

From custom CNC-cut inserts to complete shadow board systems, we’ll help you create a setup that works for your team and equipment.

Want to find out how Suttons can improve your tool control? Contact us today for a no-obligation chat with our packaging specialists.