What is ESD packaging, and why does your business need it?

If your business manufactures or handles electronic components or devices, proper protection from electrostatic discharge (ESD) is essential. Proper ESD packaging is key to protecting sensitive products such as microchips, PCBs, semiconductors, and any electronic equipment that contains these parts.

This guide will explain ESD packaging and its importance to your operations. We will also explore the various materials and packaging types available.

Contents

What is electrostatic discharge (ESD)?

Electrostatic discharge (ESD) refers to the release of static electricity when two objects come into contact. A typical example is the shock of touching a metal object after walking across a carpet. While this might be a minor inconvenience in everyday life, it can lead to significant damage in industrial settings.

For electronic components like semiconductors and microchips, even a tiny ESD event can cause failure, reducing the lifespan of products or rendering them completely inoperable. Therefore, protecting sensitive devices from ESD is essential throughout the entire supply chain, from manufacturing to shipping.

Why is ESD protection important?

ESD poses a serious risk to electronic products. Components like PCBs (printed circuit boards) and microchips rely on materials that are highly susceptible to static damage. When exposed to static electricity, these components can fail, leading to defects, malfunctions, and shortened product lifespans.

Adequate ESD packaging minimises these risks by preventing the buildup of static charges and offering physical protection during handling, storage, and transit.

The role of ESD packaging in protecting electronics

While manufacturing can create ESD-protected environments (EPAs) during production, they can be exposed to various static hazards once products leave the factory. The risk of ESD damage increases during shipping or while being handled by subcontractors or third parties.

ESD packaging is vital for ongoing protection, ensuring sensitive products remain safe from electrostatic damage throughout the supply chain.

How ESD packaging works

ESD packaging prevents static buildup, dissipates any charges that may already be present, and offers physical protection from mishandling. It helps protect items from electrostatic discharge throughout a product’s lifecycle.

Several different types of ESD packaging exist, each designed to meet specific needs depending on the level of protection required.

Types of ESD packaging

ESD packaging has four primary categories: shielding, conductive, dissipative, and anti-static. Let’s examine each:

1. Shielding

ESD packaging with shielding properties prevents electrostatic discharge by creating a barrier around the product. It reduces the potential risk of static build-up and minimises the risk of discharge.

Shielding packaging is designed to protect products from static electricity and physical damage.

2. Dissipative

Dissipative materials slow the flow of electricity, minimising the power of any electrical charge. These materials help to safely disperse static electricity before it can reach the sensitive components within the packaging.

Dissipative packaging typically has a surface resistance of 10^5 to 10^11 ohms.

3. Conductive

Conductive packaging directs electric charges away from sensitive components using materials that allow static electricity to flow freely. This prevents the accumulation of static charges that could damage the contents.

Conductive packaging usually has a surface resistance of 10^2 to 10^5 ohms and is highly effective at preventing ESD damage.

4. Anti-static

Anti-static packaging prevents tribocharging, a process in which two materials come into contact and generate static electricity. By reducing tribocharging, anti-static packaging lowers the likelihood of sparks or ignition during transport.

ESD packaging categories

In addition to material types, ESD packaging is categorised based on its interactions with electrostatic discharge-sensitive (ESDS) components. These include:

- Intimate packaging: This type of packaging is directly in contact with sensitive products and offers the highest level of protection. It is often used within ESD-protected environments or for general transport.

- Proximity packaging: Encloses products without direct contact, typically used with intimate packaging.

- Secondary packaging: Provides additional protection but should not touch sensitive components directly.

Common ESD packaging solutions

Several proven ESD packaging solutions are widely used in industries that require electrostatic protection. Some of the most popular options include:

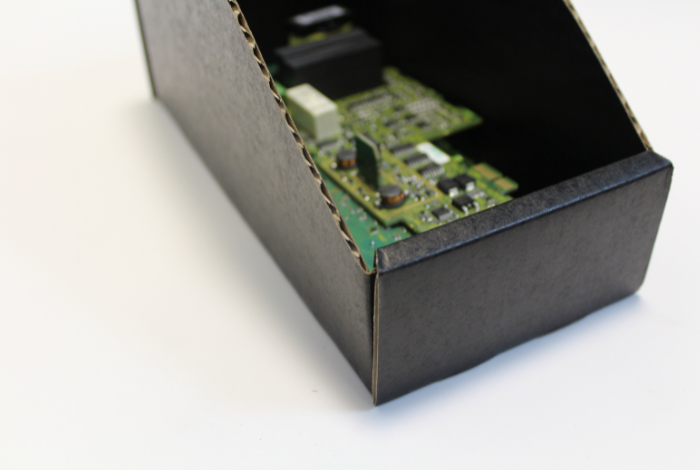

- Corstat-coated fibreboard: Known for its conductive properties, Corstat packaging offers protection by creating a Faraday cage effect, effectively shielding contents from static electricity. It is also recyclable and available in various sizes.

- Corriplast (corrugated plastic): Corriplast combines the benefits of Correx with conductive properties. It is durable, moisture-resistant and ideal for repeated use in various shipping environments.

- SSI Schaefer moulded plastic containers: Robust and durable; these containers are designed for high-volume use and long-term protection in handling and transportation.

- ESD bags: A cost-effective option for smaller or less delicate components, ESD bags are often used for lower-risk applications. However, they are less suitable for sharp objects that could puncture the material.

- Foams: Adding foam inserts to ESD packaging can provide additional physical protection, preventing damage from impacts and offering static protection.

Choosing the right ESD packaging for you

When selecting the appropriate ESD packaging, consider the level of sensitivity of the products you’re protecting. Ensure that you understand the specifications of the electronic components that you handle and choose the packaging that meets those needs.

Also, consider the costs, environmental impact, and potential for reusability. While some ESD solutions might have a lower upfront cost, reusable options can save you money in the long term by reducing waste and lowering overall packaging costs.

Summary

Selecting the right ESD packaging is a critical decision that involves balancing materials choice, performance, environmental impact, and cost. We offer various packaging solutions to protect sensitive electronic components at Suttons Performance Packaging.

For expert advice or to discuss your ESD packaging requirements, get in touch with our team today. We are here to help you find the best solutions for your needs.